Multifaceted Evaluation of Plastic Degradation

Identifying Causes of Degradation and Understanding Effects of Degradation

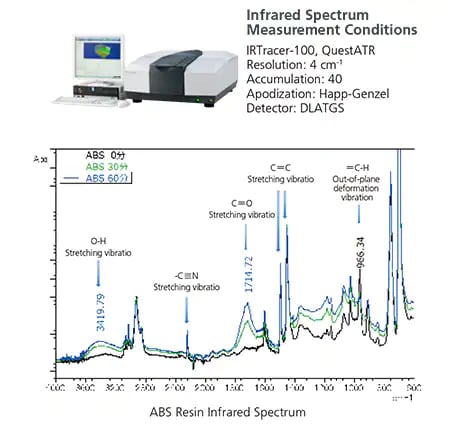

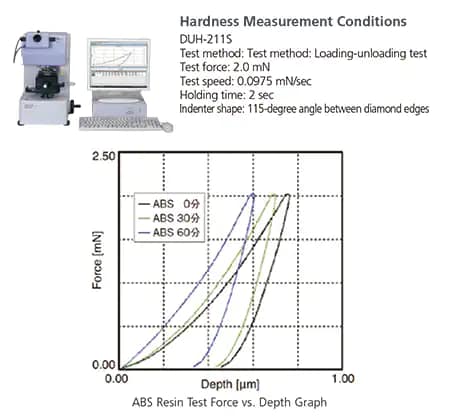

Plastic properties can change or degrade not only due to heat, various organic solvents, or acidic or alkaline solutions, but also due to UV rays. In particular, if plastics are used outdoors (as automotive exterior parts, for example), they require UV resistance. Developing plastics resistant to UV degradation requires understanding the causes and effects of the degradation. A deeper understanding can be determined from multifaceted evaluations. As an example of multifaceted degradation evaluation, ABS resin pellets were irradiated with UV rays and then changes in the mechanical properties at the resin surface were evaluated. An FTIR system was used to measure an infrared spectrum to evaluate macromolecular structural changes and a dynamic ultra micro hardness tester was used to measure the hardness of the resin surface.

UV irradiation Conditions: Ozone-free mercury-xenon lamp at less than 45 mW/cm2 from 300 to 450 nm

-

-

- The results confirmed increased absorption due to O-H stretching vibration or C=O stretching vibration when UV irradiation time was increased. Decreased peak height was confirmed at 966 cm-1. That indicates absorption due to =C-H out-of-plane deformation vibration of the trans-vinylene group contained in the butadiene. On the other hand, no significant changes were observed in the nitrile group -C≡N stretching vibration peak (near 2240 cm-1) or the styrene C=C stretching vibration peaks (near 1500 and 1450 cm-1 due to benzene ring angular vibration). These results suggest that ABS oxidation progresses from portions of the butadiene affected by UV rays.

- The fact that penetration depth in respective sample surfaces decreased as UV irradiation time increased confirms that the surfaces became harder.

Both the infrared spectrum measurement and hardness measurement results show a tendency for properties to change as the UV irradiation time increases. It suggests that UV rays decrease the polymer’ s original flexibility due to oxidative degradation of butadiene at the sample surface, which makes it more prone to cracking.

- Thermal degradation can be efficiently identified using a thermal degradation library.

- Measurement data can be saved in a private library to improve analysis capabilities by using previous measurement results for identification.

- With the ability to measure hardness without measuring indentation size, the series can evaluate the hardness of even polymer materials that are difficult to indent.

- Micro areas can be evaluated, such as on tiny samples or surface layers, because hardness can be measured based on tiny indentation displacements.