Troubleshooting Carryover Peaks

With recent detector improvements, the sensitivity of today's detectors has allowed for the use of low concentration standards that are an order of magnitude lower than earlier ones.

Carryover is a phenomenon that is dependant on the sample compound.

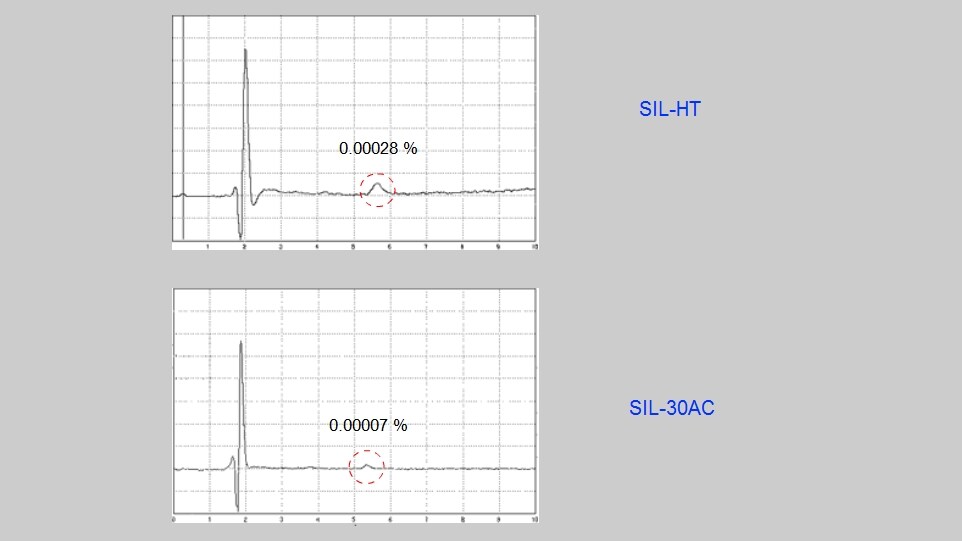

A number of improvements to the injection process have greatly reduced the effects of carryover in the Shimadzu Prominence HPLC series.

Installation of the optional, additional rinse pump provides a multi-liquid capability that reduces carryover to less than 0.0001% for the highly adsorptive chlorhexidine.

Are the carryover expectations realistic?