SALD-BC Series - Features

SALD-BC Series Batch Cell for SALD Series

SALD-BC Series Features

Measurement Possible by Small Amounts of Samples (Measured Particles) and Medium Liquid (Dispersion Medium)

When performing circulation measurement, all of the flow cell, dispersing bath (sampler) and circulation tubing must be filled with suspension (sample and dispersion medium). When using a laser diffraction particle size analyzer, the sample concentration needed for measurement is about 100 ppm (wt%). Thus, the amount of sample may appear to be not so large, but some customers do have a need to perform measurement using even smaller amounts especially when measuring valuable and expensive samples. Also, some customers who use organic solvents as the dispersion medium want to use less suspension for measurement so that they can reduce waste solutions.

The volume of the batch cell is a mere 12 cc. Whereas, with circulation measurement, the volume of the dispersing bath alone is 280 cc on the SALD-2200 and SALD-7100 and 400 cc on the SALD-3100.

Consequently, use of a batch cell enables measurement to be performed using less sample and dispersion medium compared with circulation systems.

Particle Sedimentation Minimized by Vertical Motion of Stirring Plate

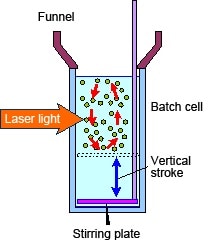

Fig. 1 Structure of Batch Cell

With a batch cell, sedimentation of particles would affect measurement since the suspension (sample and dispersion medium) is not circulated and is in a still state. Since larger sizes of particles sediment more quickly, the particle size distribution might become smaller over time. Since measurement durations are short on the SALD series, the affect of this is considered to be relatively small. Attention, however, is required when measuring samples having a wide distribution width.

The batch cell for the SALD series (compatible with SALD-3101, SALD-2201 and SALD-7101) uses the vertical motion (see Fig. 1) of the stirring plate to suppress sedimentation of particles and ensure accurate measurement of particle size distribution. There is also no adverse affect arising from use of a stirrer when measuring magnetized particles since it does not incorporate a magnet unlike a magnetic stirrer.

Funnel Lessens the Possibility of Spilled Samples

A tetrafluoroethylene resin funnel (see Fig. 1) is provided to avoid suspension (sample and dispersion medium) being spilled outside when pouring it into the batch cell. This lessens the possibility of suspension getting on your hands and fingers. A major advantage of this is demonstrated when acid or organic solvents are used as the dispersion medium. When solvent transfers to the outer side of a batch cell, appropriate scattered light cannot be detected, which causes measurement error. Use of a funnel solves this problem.

Note

When particles of 100 µm or less are measured, the affect of sampling error increases if the distribution width is particularly wide since the number of particles in an appropriate concentration decreases.

The affect of sedimentation of particles also increases when particles of 100 µm or more are measured and the distribution width is wide. With large particle densities, the affect of sedimentation must also be taken into consideration at also particle sizes of approximately several µm. In cases such as these, circulation measurement using a sampler is recommended.

* Appearance and specifications are subject to change without notice.