HyperVision HPV-X3 - Applications

High-Speed Video Camera

Material

DIC Analysis for High-Speed Tensile Testing of CFRPs

-

Both static and dynamic material properties, such as impact characteristics, are important for understanding the behavior of materials. Carbon fiber reinforced plastics (CFRPs) exhibit brittle fracture behavior with fracture progression that occurs instantaneously upon damage, and observing this phenomenon requires high-speed video cameras with excellent recording speeds and resolution. The improved resolution of the image sensor in the HPV-X3 improves camera performance for DIC analysis.

-

Recording speed: 20 Mfps, Test speed: 10 m/s, Specimen width: 12 mm

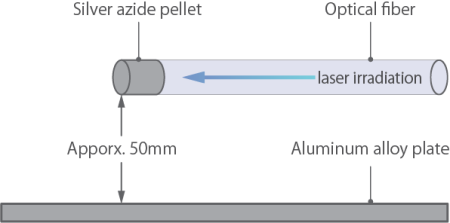

Observing Blast and Shock Waves During Detonation of Micro-Explosives

- A silver azide pellet was detonated with a laser and the resulting blast and shock wave propagation was visualized in Schlieren images. The shock wave propagated around the blast wave and its reflection was visualized clearly in an aluminum alloy plate.

Recording speed: 1 Mfps, Field of view width: approx. 250 mm

- Images of the area around a silver azide pellet during detonation were captured at 20 Mfps. The images captured a blast wave that appeared approx. 450 ns after laser irradiation of the pellet, which was followed by the progression of a shock wave around the blast wave.

Recording speed: 20 Mfps, Field of view width: approx. 5 mm

Images captured by: Specially Appointed Associate Professor Kiyonobu Otani, Institute of Fluid Science, Tohoku University

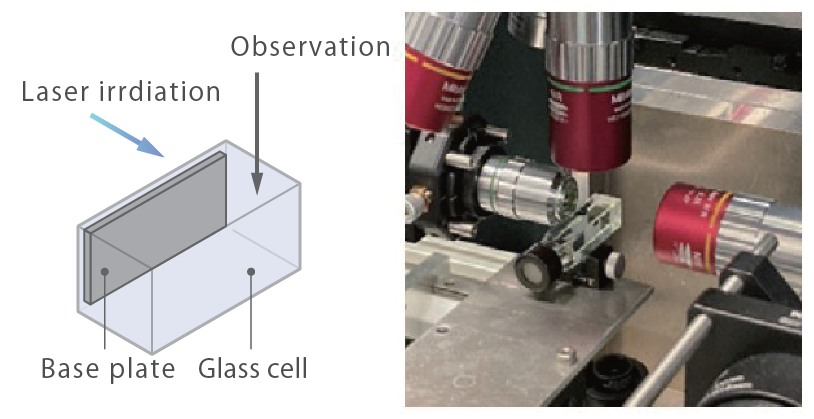

Observing Crack Progression During Ring-on-Ring Testing of Glass

- Ring-on-ring testing was performed on reinforced glass and images were captured of the cracks that occurred during failure. (Reference standard: ASTM C1499)

Recording speed: 10 Mfps, Field of view width: approx. 45 mm

Life Science

-

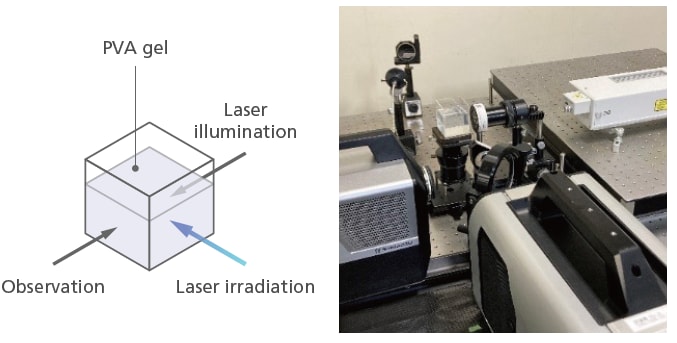

Expansion and Contraction of Bubbles in Polyvinyl Alcohol (PVA) Gel

Images were captured of bubbles being formed while PVA gel was irradiated with a laser. Bubbles were observed to repeatedly expand and contract inside the gel. Images captured by the camera show the progression of shock waves produced when the bubbles were formed and collapsed. -

-

Bubble Formation

Recording speed: 20 Mfps, Field of view width: approx. 75 mm -

Bubble Collapse

Recording speed: 20 Mfps, Field of view width: approx. 20 mm

Images captured by: Associate Professor Tokitada Hashimoto, Department of Mechanical Engineering, Faculty of Science and Engineering, Saga University

Observing the High-Frequency Oscillation of Microbubbles

-

Images were captured of microbubbles that formed in water when the water was irradiated and heated locally with a laser. The microbubbles first expanded then contracted and the images show a jet flow that occurs during contraction as the bubble disappears.

-

Recording speed: 20 Mfps, Field of view width: approx. 110 um

Images captured by: Associate Professor Kyoko Namura, Department of

Micro Engineering, Graduate School of Engineering, Kyoto University

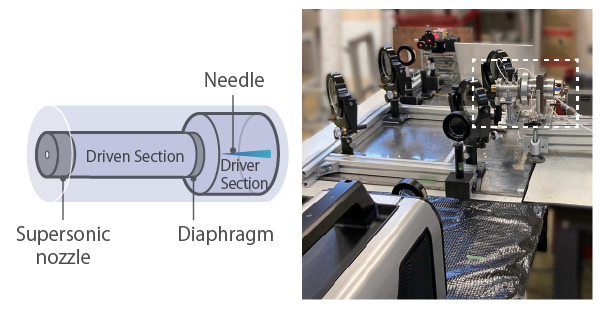

Observation of Shock Waves in Shock Tubes

-

The shock wave generated when releasing air at eight times atmospheric pressure was captured using a Mach-Zehnder interferometer. The shock tube consists of a driver section, a driven section, a supersonic nozzle, and a needle. A plastic diaphragm is placed between the driver and driven sections, and during the test, the diaphragm is ruptured using the needle to generate the shock wave.

-

Recording speed: 1 Mfps

Images captured by: Associate Professor Tokitada Hashimoto, Department of Mechanical Engineering, Faculty of Science and Engineering, Saga University