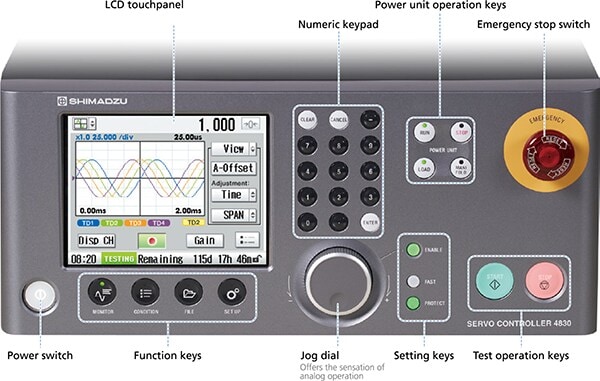

4830 Controller - Features

Servopulser Control Unit

4830 Controller Features

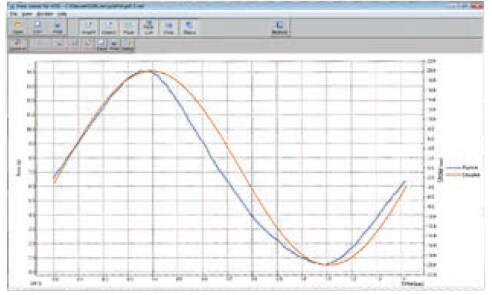

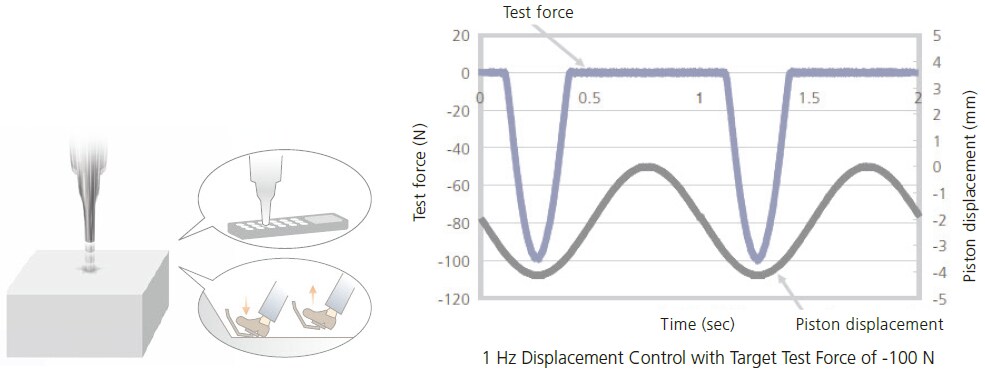

- Waveform Generation with Excellent Reproducibility

Full digital control with control parameter auto-tuning and waveform distortion correction functions*1 achieves faithful load waveform reproducibility. - Simultaneous Testing on 4 Units Max.

Synchronous connection of controllers enables synchronous control of up to four testing machines (actuators). The controller also is equipped with a phase correction function that allows the phase difference between feedback signals to be controlled to a fixed level. - Test Force Control on Specimens with "Play"

Stable peak-value control is achieved using the test force, even for specimens with "play" (where no test force is applied). - World-Class Basic Performance

24-bit high-resolution A/D converter and detector output linearization function achieve ±0.5 % accuracy of indicated values on a standard system. *2 - Simple Operation

The graphic user interface (GUI) using color LCD monitor and touch panel, and dedicated function keys allow operations to be conducted quickly and interactively. This means that even first-time users can perform operations with ease in a short time. - Waveform Display Functions

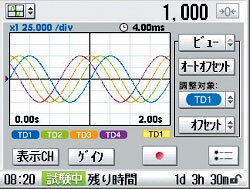

Test waveform display functions installed as standard allow the realtime display of time graphs and X-Y graphs, and digital reading of numerical values on graphs. - USB Interface

Connection to a PC via the USB interface allows controller functions to be considerably enhanced. (Dedicated software is optional.)

*1 Optional Windows software for 4830 series

*2 Provided as standard for the E-type, U-type and L-type loading frames, and Force Simulator

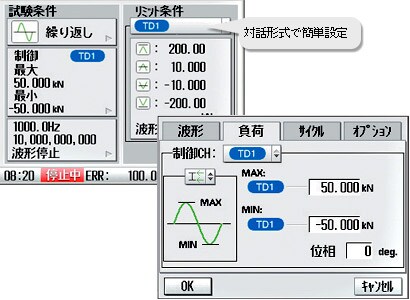

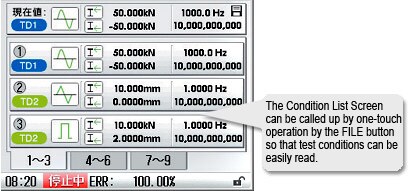

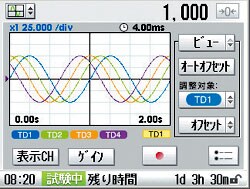

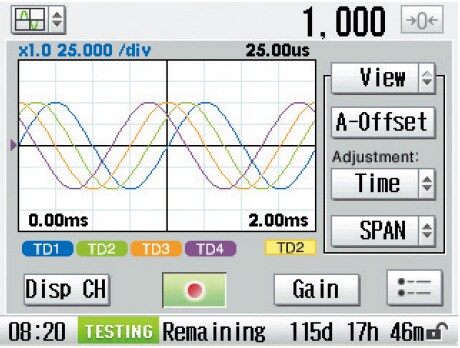

Screen Example

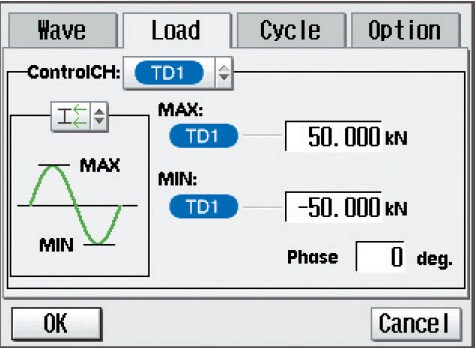

- Setting conditions

Test conditions can be set interactively via the touch panel, allowing even first-time users to perform setup with ease.

- Executing tests

During test execution, execution progress is indicated by numerical values and the waveform is displayed.

Numerical value display

Time graph

X-Y graph

Peak graph

* Appearance and specifications are subject to change without notice.

Controller for Dynamic and Fatigue Testing Systems Servo Controller 4830

Dramatically Improves Accuracy in Evaluating Endurance and

Dynamic Strength of Samples Ranging From Materials to Actual Samples

This controller is designed specifically for dynamic testing machines based on Shimadzu's long history of supplying dynamic and fatigue testing systems and based on feedback from many of our customers. It boasts high performance and exceptionally user-friendly operability. Equipped with a 24-bit high-resolution analog-digital converter, and featuring excellent reproducibility of load waveforms due to fully digital control, it can accommodate a wide variety of dynamic testing requirements.

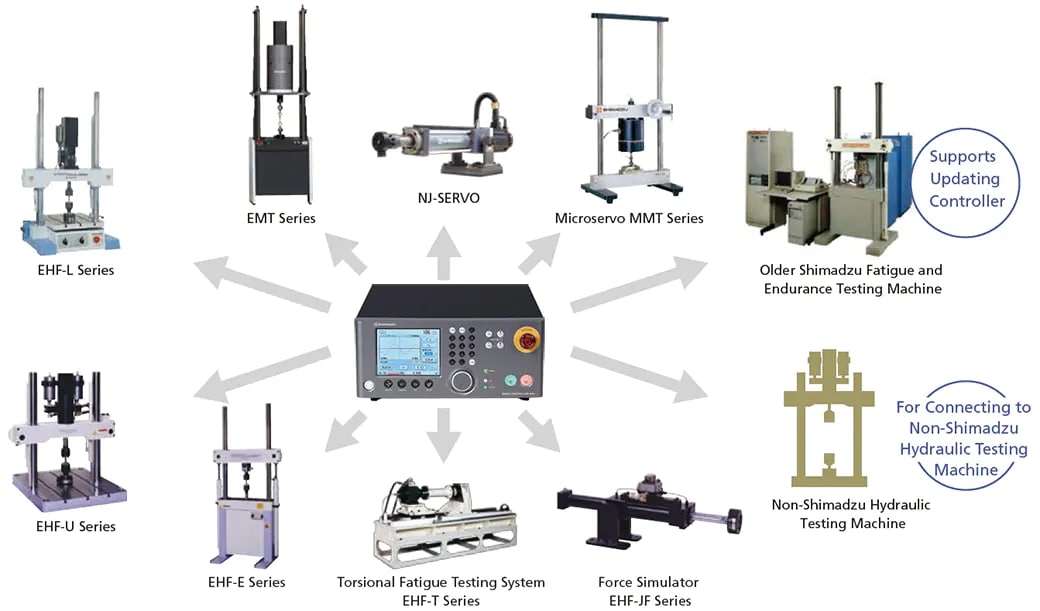

Connectivity to the Entire Family of Shimadzu Dynamic and Fatigue Testing Machines and Non-Shimadzu Hydraulic Testing Machines

Note: Excludes HITS series and USF-2000 models.

The controller can be connected to Servopulser series electric-hydraulic, electromagnetic force, and pneumatic testing systems, jack systems (actuators), and various other testing machines.

It also can be used to update older Shimadzu systems, or controllers for non-Shimadzu hydraulic testing machines.

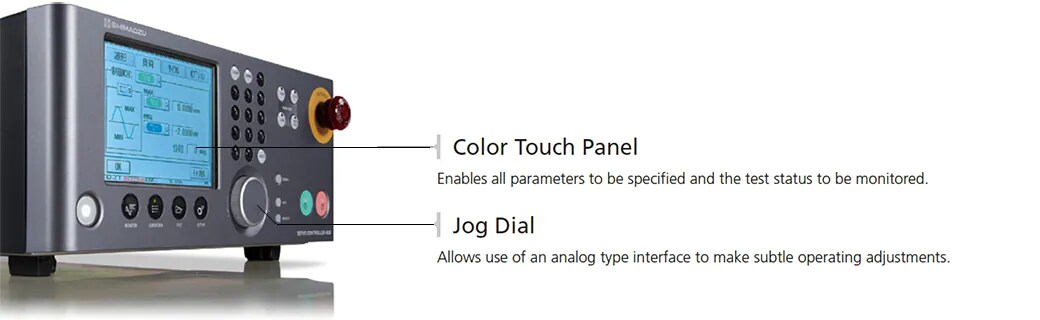

Very Easy to Operate

Testing parameters can be specified using the touch panel or jog dial. Test parameter settings, such as test force and displacement, can be changed at any time during tests.

Loading Parameter Settings

Waveform Display Functions

Jog Dial

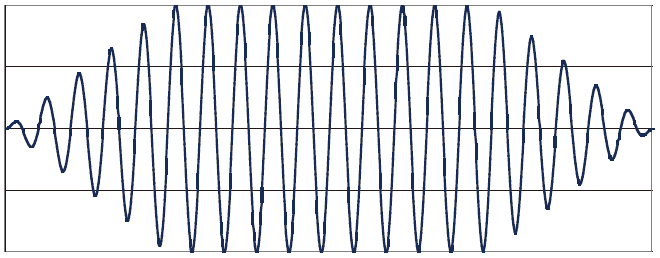

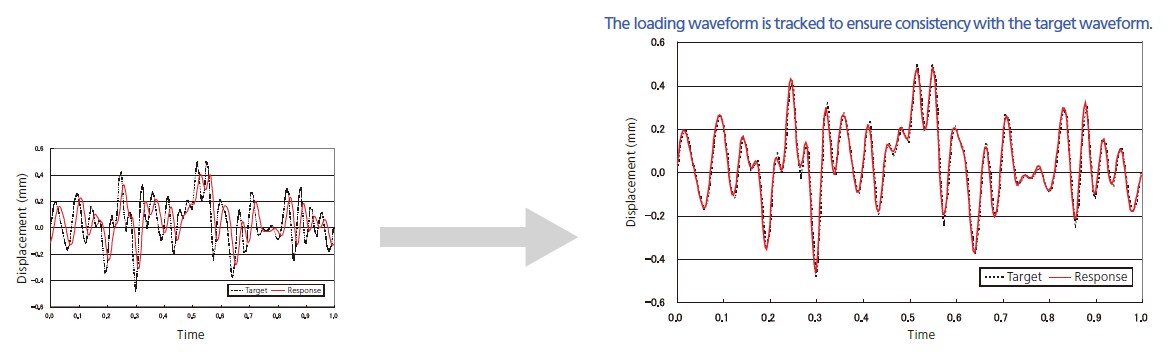

Autotuning and Automatic Gain Control

Functions Ensure Loading Waveforms are Input Precisely

The autotuning function automatically determines the optimal parameters for controlling tests based on the actual test status and sample material. The automatic gain control function makes corrections so that peak values in loading cycles are consistent with parameter settings. Together, these functions help ensure precise loading waveforms. Consequently, even operators performing tests for the first time can automatically achieve highly accurate testing by simply setting parameters and starting testing.

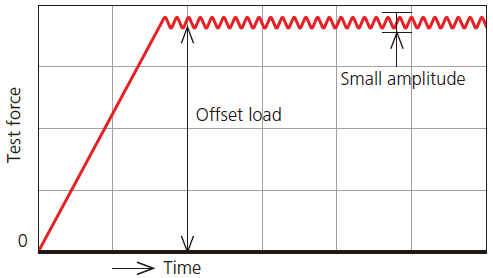

Offset Load Tests

Offset load testing makes it possible to accurately apply offset micro loads while applying large test force loads.

Slow Start/Stop

A slow start/stop time setting can be specified for tests. This eliminates operating differences between operators and helps ensure highly reproducible tests.

Push Test Function

This allows controlling peak test force values in a stable manner, even for samples with "play" (where no test force is applied).

Waveform Distortion Correction Function

Because it can correct for loading mechanism-specific periodic strain, it can cancel out unwanted strain components and accurately control loads according to the target waveform.

Broad Applicability

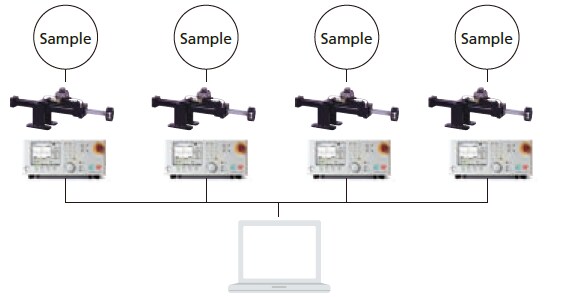

Up to four testing machines can be operated for synchronous testing. X-T, X-Y, peak graphs, and a variety of other waveforms can be displayed. By connecting to a computer via a USB cable, a wide variety of test settings and sophisticated data acquisition settings can be specified.

Multiple Tests

A single computer can be used to simultaneously perform up to four different tests using different test parameters. For example, four endurance tests can be performed in parallel to acquire peak values and cycle data.

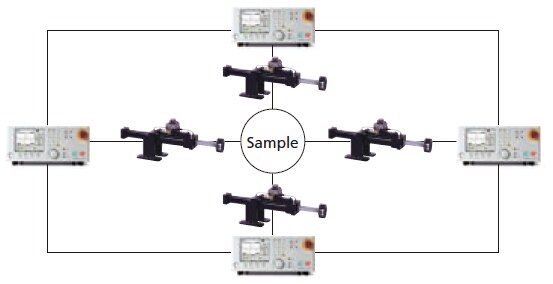

Synchronized Testing

Control and measurements of up to four testing machines can be synchronized by synchronizing the controller connection. The phase can also be freely set for each actuator.

Updating older controllers to the latest model improves control performance and enables using the most up-to-date software.