Optional Accessories and Systems

Servopulser series systems allow selection of the optimal combination of units based on testing objectives. In addition, an extensive selection of optional testing equipment, such as various testing jigs, detectors, and atmospheric control testing units, is available. For more details, refer to the separate optional accessories brochure.

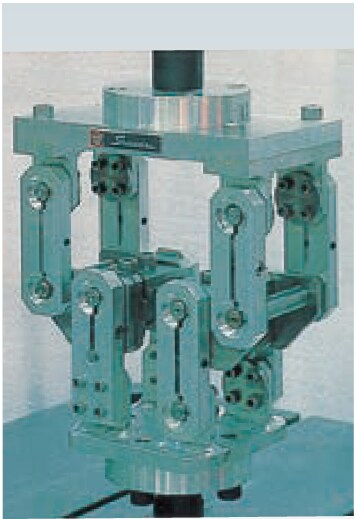

Tensile and Compression Test Jigs

Front-Opening Hydraulic Grip

Designed for full-amplitude tensile and compression fatigue testing, these grips offer superior ease-of-operation and ensure high-accuracy testing for a wide range of tests.

| Maximum test force | ±20 to 200 kN (multiple capacities available) |

|---|---|

| Operating temperature range | RT to +50 °C |

| Applicable sample | Rod / flat plate |

Manual Non-Shift Plate Grip

These grips are designed for full-amplitude tensile and compression fatigue testing of flat plate materials and feature a simple and efficient construction.

| Maximum test force | ±5 to 100 kN (multiple capacities available) |

|---|---|

| Operating temperature range | RT to +50 °C -196 to +300 °C |

| Applicable sample | Flat plate |

Split Flange Rod Grip

These grips allow samples to be secured easily and firmly. They are ideal for full-amplitude tensile and compression fatigue testing of round rod samples.

| Maximum test force | ±10 to 200 kN (multiple capacities available) |

|---|---|

| Operating temperature range | RT to +100 °C -196 to 300 °C |

| Applicable sample | Rod |

Pin-Type Grip for Flat Samples + Dynamic Strain Gauge

(for gauge length displacement)

These grips are designed for half-amplitude tensile fatigue testing.

Note: Supports only tensile testing.

| Maximum test force | +6 kN/10 kN |

|---|---|

| Operating temperature range | -196 to +300 °C (±6 kN) -20 to +300 °C (±10 kN) |

| Applicable sample | Flat plate (max. 30 mm wide and 5 mm thick) |

Non-Shift Wedge Grip for Static Testing

These grips can only be used for static testing. These high-capacity grips apply the self-tightening action of a wedge.

Note: Supports only tensile testing.

| Maximum test force | ±20 to 250 kN (multiple capacities available) |

|---|---|

| Operating temperature range | 0 to +120 °C |

| Applicable sample | Rod / flat plate |

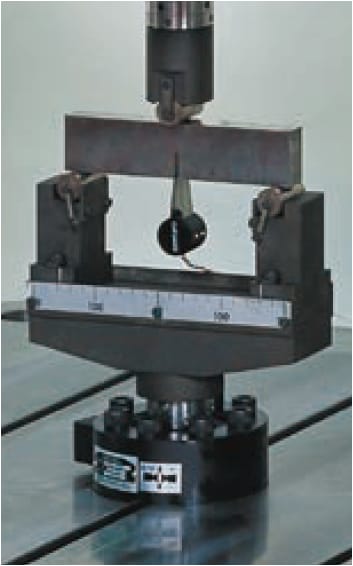

Grips for CT Test Samples + Clip Gauge

These compact grips are designed specifically for tensile test samples and are compliant with ASTM E399 and E1820 standards. They can be used for tests performed to determine fracture toughness or crack propagation.

Note: Supports only tensile testing.

| Maximum test force | ±6 to 80 kN |

|---|---|

| Operating temperature range | RT to +100 °C -20 to 300 °C |

| Applicable sample | CT test sample |

Bolt Testing Jigs

Screw Tensile Test Jig

This jig is for tensile fatigue testing of various nuts and bolts. Various grips sizes are available depending on the bolt size.

| Maximum test force | ±100/250 kN |

|---|---|

| Operating temperature range | RT to +50 °C |

| Applicable sample | Nuts/bolts |

Screw Looseness Test Device

This device allows testing various parameters to determine the loosening process of bolts. It applies a vibrational displacement in the thread tightening direction and in the perpendicular direction and then measures the change in tightening force in relation to the number of vibrations.

| Maximum test force | ±20 kN |

|---|---|

| Operating temperature range | RT to +100 °C -20 to +300 °C |

| Applicable sample | CT test sample |

Compression and Bending Test Jigs

Compression Plate

Compression plates are available with both he top and bottom fixed or with the top compression plate mounted on a spherical seat.

| Maximum test force | 20 to 500 kN (multiple capacities available) |

|---|---|

| Operating temperature range | RT to +250 °C |

| Applicable sample | 60 to 220 mm dia. |

3-Point/4-Point Bending Test Jig

(for partial half-amplitude fatigue testing)

| Maximum test force | 2kN |

|---|---|

| Max. dynamic bending moment | 50 N/m |

| Operating temperature range | RT to +100 °C -196 to +300 °C |

| Jig dimensions | Lower span: 30 to 100 mm Upper span: 15 to 50 mm |

Uniform Bending Test Jig (for full-amplitude fatigue testing)

This jig uses ball bearings at each support point to apply uniform bending loads.

| Maximum test force | ±2 to 10 kN |

|---|---|

| Max. dynamic bending moment | ±20 to 250 N/m |

| Operating temperature range | RT to +50 °C -196 to +200 °C |

CTOD Bending Test Jig + Clip Gauge

This jig is for CTOD bending tests compliant with ASTM E339. It is used for fracture toughness testing.

| Maximum test force | 50/100 kN |

|---|---|

| Max. dynamic bending moment | 2/6 k N/m |

| Operating temperature range | RT to +100 °C -196 to +300 °C |

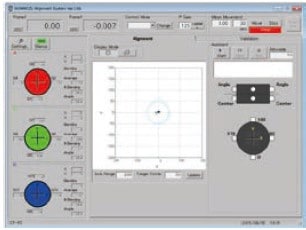

Axis Adjustment System

Consisting of an axis adjustment unit, axis center sensor testing sample, strain amplifier unit, and dedicated axis adjustment software, this system allows adjusting the tilt between grips and adjusting the axis centers in the horizontal direction. It allows users to obtain highly reliable data by eliminating any bending stresses on samples.

![]()

Various Environmental Control Testing Systems

Various environmental control testing systems are required to simulate harsh environments or environments where materials are actually used, such as thermostatic, high-temperature, or extremely low-temperature environments. Therefore, an environmental control system can be added in the large testing space provided by the Servopulser series system.

See page 58.

![]()

News / Events

-

SAMPE 2025

May 20-21

Indiana Convention Center

Indianapolis, IN

Booth # T12

-

MD&M West 2025

February 4-6

Anaheim Convention Center

Anaheim, CA -

International Elastomer Conference 2024

September 10-12

David L. Lawrence Convention Center

Pittsburgh, Pennsylvania

-

SAMPE 2024

May 21-22

Long Beach Convention Center

Long Beach, California

Booth # H18

-

Medical Design & Manufacturing West 2024

February 6-8

Anaheim Convention Center

Anaheim, California

Booth #2283