Reducing Sugar Analysis System - Features

Nexera Reducing Sugar Analysis System

Unique Detection Method Provides Excellent Quantitative Reliability

Unique Detection Method

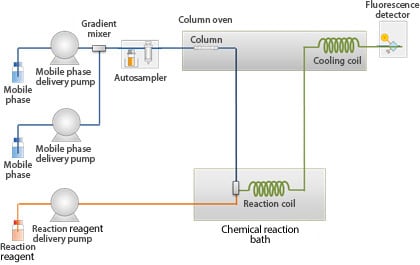

The Nexera reducing sugar analysis system is specially designed to selectively detect sugars using post-column reaction technology and a fluorescence detector. Thanks to the post-column fluorescence derivatization method, which uses boric acid and arginine as the reaction reagents, this system can quantify sugars in samples with a number of impurities, selectively and with high sensitivity.

Detection Principles

When sugars are heated with arginine in the presence of boric acid, they produce fluorescent derivative.

After the sugars are separated with boric acid anion exchange chromatography and ligand exchange chromatography, the sugars are detected by a fluorescence detector due to a reaction with arginine/boric acid reagent, which is delivered continuously.

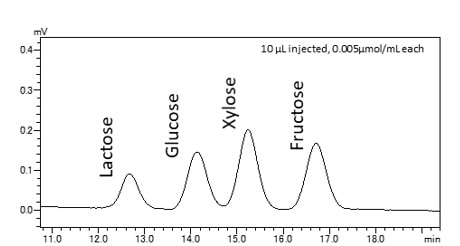

High Sensitivity Analysis of Sugars

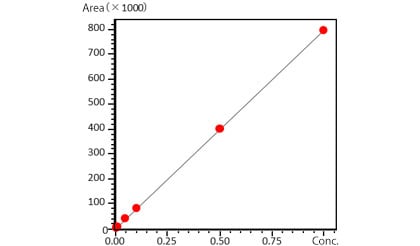

The derivatized sugars are detected with high sensitivity by the RF-20Axs fluorescence detector. The analysis of low concentration sugars, which was difficult with conventional refractive index detectors, can now be performed by the reducing sugar analysis system. Additionally, this detection method features a wide dynamic range, so analysis can be performed without changing the dilution factor, even for samples with concentration differences.

Analysis of a Standard Mixture of Sugars Using the Nexera Reducing Sugar Analysis System (0.005 µmol/mL, 10 µL injection)

Glucose Linearity Obtained Using the Nexera Reducing Sugar Analysis System (0.005 µmol/mL to 1 µmol/mL, 10 µL injection)

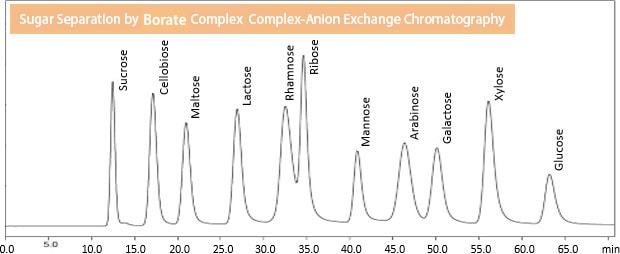

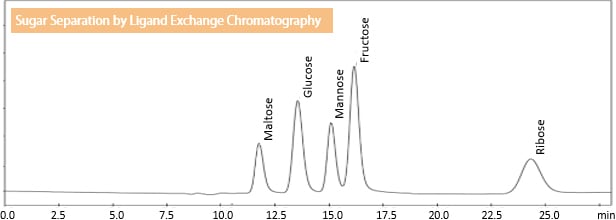

Compatible with Any Separation Mode

Sugars are highly hydrophilic compounds, so anion exchange chromatography and ligand exchange chromatography are used rather than reversed phase chromatography which separates compounds via hydrophobicity interactions. The separation mode must be selected to suit the analytical purpose. The Nexera reducing sugar analysis system allows a variety of sugars to be analyzed.

Ensures Highly Reliable Analysis Regardless of Operator Skill Level

Protects Expensive Columns:FlowPilot

HPLC columns can be damaged by sudden pump starts and stops or extreme gradient changes. The Nexera automatically uses FlowPilot (Smart Flow Control) to increase the flow rate gradually to the set point. There is no need to create startup protocols for each analysis.

Mobile Phase Levels Measured in Real Time

Mobile phase monitor(optional) can be used to monitor the volume of mobile phase or autosampler rinse solution in up to twelve containers. The containers can also be checked remotely from a smart device. You will no longer need to worry about running out of mobile phase mid-analysis, because the device will notify you before starting the run if the volume remaining is too low.

Auto-Diagnostics and Recovery

In rare cases, air bubbles can form in the mobile phase and cause problems if inhaled into the pump. The Nexera has the ability to monitor baseline changes and pressure fluctuations to check for abnormalities. When it detects an unusual fluctuation, it can automatically pause the analysis, purge the flow path, and restart analysis once it has confirmed recovery to normal pressure.

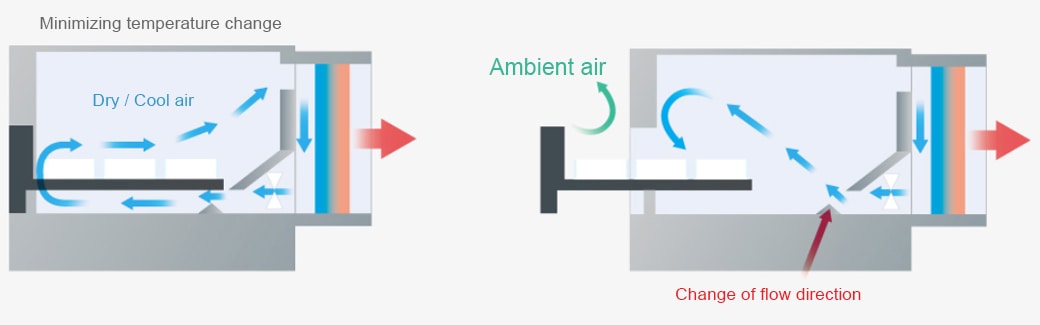

Unique design to ensure reliable sample cooling

The SIL-40 series has a “direct access” function which allows extra sample vials or MTPs to be added even during analysis. Dry air flow control maintains the temperature inside the autosampler and protects the samples from condensation.

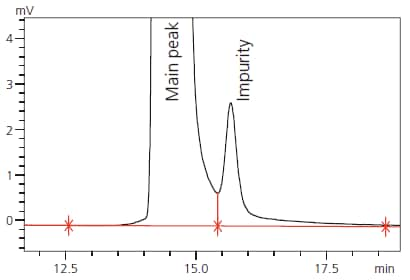

Consistent Peak Splitting

Manually setting the baseline for fused peaks is time-consuming, and the peaks may be split differently depending on the user. The i-PeakFinder has adjustable parameters for different analyses, allowing you to consistently apply the best baseline in each situation.

Baseline not set

Setting a baseline provides complete separation

ANALYTICAL INTELLIGENCE

- Automated support functions utilizing digital technology, such as M2M, IoT, and Artificial Intelligence (AI), that enable higher productivity and maximum reliability.

- Allows a system to monitor and diagnose itself, handle any issues during data acquisition without user input, and automatically behave as if it were operated by an expert.

- Supports the acquisition of high-quality, reproducible data regardless of an operator’s skill level for both routine and demanding applications.