Gas Chromatograph-Mass Spectrometry

GC-MS, GC-MS/MS Instruments

Gas chromatography/mass spectrometry (GC/MS) is an analytical technique that combines gas chromatography and mass spectrometry to identify unknown substances or contaminants. Due to its precision and accuracy, GC/MS can be used for a variety of applications and industries including food safety, pharmaceuticals, environmental and forensic testing.

Shimadzu is one of the world’s leading manufacturers of GC-MS instruments, producing a range of gas chromatograph mass spectrometers. Shimadzu's GC-MS boast ultra-high sensitivity and efficiency and are designed to maximize lab productivity while minimizing environmental impact.

We offer a comprehensive suite of GC-MS systems for every application, from our triple quadrupole GC-MS/MS (GCMS-TQ8040 NX and GCMS-TQ8050 NX) to our single quadrupole GC-MS (GCMS-QP2020 NX and GCMS-QP2050), as well as a variety of accessories and software to enhance your GC-MS analysis. Here’s a guide to GC-MS and Shimadzu’s GC-MS instruments, which offer superior performance, enhanced sensitivity, durable hardware, and reliable operation for all our users and their applications.

Recommended

Advanced Gas Chromatography/Mass Spectrometry (GC/MS) Solutions

Gas chromatography/mass spectrometry (GC/MS) is a powerful analytical technique used across industries for precise identification and quantification of chemical compounds. By combining gas chromatography (GC) with mass spectrometry (MS), this technique enables laboratories to achieve high sensitivity and accuracy in complex sample analysis. GC/MS is widely applied in pharmaceuticals, environmental testing, forensic science, and food safety industries.

Shimadzu is a leading manufacturer of GC/MS instruments, offering cutting-edge systems designed for superior performance, enhanced sensitivity, and optimized workflow efficiency. Our portfolio includes single quadrupole and triple quadrupole GC/MS systems, tailored software solutions, and essential accessories to support various analytical applications.

Understanding Gas Chromatography/Mass Spectrometry (GC/MS)

GC/MS integrates two powerful analytical processes to provide detailed compound analysis:

- Gas Chromatography (GC): Separates volatile and semi-volatile compounds in a sample based on their physical and chemical properties.

- Mass Spectrometry (MS): Identifies compounds by measuring their mass-to-charge ratio, providing high specificity and structural information.

This combination allows laboratories to analyze complex mixtures with exceptional accuracy, making GC/MS an essential tool in scientific research and industry applications.

How GC/MS Works: A Step-by-Step Overview

- Sample Injection: A sample is introduced into the gas chromatograph’s injector, where it is vaporized for analysis.

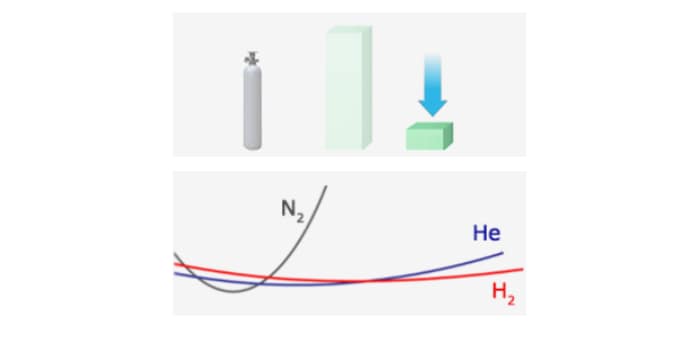

- Separation in the GC Column: The sample components are carried by an inert gas (e.g., helium) through a chromatography column, separating compounds based on their volatility and interaction with the column's stationary phase.

- Detection by Mass Spectrometry: As separated compounds exit the GC column, they enter the mass spectrometer, where they are ionized, fragmented, and analyzed based on their mass-to-charge ratio.

- Data Interpretation: The system generates a mass spectrum, allowing users to identify and quantify compounds using spectral libraries or targeted analysis methods.

Key Applications of GC/MS

GC/MS is the gold standard for various industries requiring high-precision analytical methods.

Common applications include:

- Pharmaceutical Analysis: Ensuring drug purity and detecting contaminants.

- Environmental Monitoring: Detecting pollutants and volatile organic compounds (VOCs) in air, water, and soil samples.

- Forensic Science: Identifying toxic substances, drugs, and explosives.

- Food Safety Testing: Analyzing pesticide residues and contaminants in food products.

Advantages of GC/MS Technology

- High Sensitivity and Specificity: Detects trace-level compounds with high accuracy.

- Reliable Quantification: Measures exact concentrations of substances in complex samples.

- Versatile Applications: Used across multiple industries for both qualitative and quantitative analysis.

- Automation and Efficiency: Modern GC/MS systems streamline workflows with advanced software and automation features.

Choosing the Right GC/MS System

Shimadzu offers a range of GC/MS solutions tailored to different analytical needs:

- Triple Quadrupole GC-MS/MS: Ideal for highly sensitive and selective analysis in demanding applications.

- Single Quadrupole GC-MS: Reliable and cost-effective solution for routine testing and research.

- GC-MS Components & Accessories: Enhancing system performance and operational flexibility.

Frequently Asked Questions (FAQs)

What are the principles of gas chromatography/mass spectrometry?

GC/MS combines gas chromatography, which separates compounds, with mass spectrometry, which identifies them based on mass-to-charge ratios. This integration enables highly sensitive and accurate chemical analysis.

Why is gas chromatography coupled with mass spectrometry?

GC allows effective separation of sample components, while MS provides precise identification. Together, they enhance sensitivity, selectivity, and compound detection capabilities.

What are the benefits of GC-MS analysis?

GC-MS offers superior analytical precision, enabling trace-level detection of compounds in complex samples. It is essential for regulatory compliance, product safety, and scientific research.

Is GC-MS used for qualitative or quantitative analysis?

GC-MS supports both qualitative analysis (compound identification) and quantitative analysis (measurement of concentrations), making it a versatile analytical tool.

What is the process of GC-MS testing?

GC-MS testing involves sample preparation, injection into the GC column, separation, ionization, fragmentation, and mass spectral analysis to determine the composition and concentration of target compounds.